Introduction

In the vast, ever-evolving landscape of digital culture, few figures embody the surreal blend of nostalgia, irony, and collective fabrication quite like Burt Thicke. If you search for his name online, you’ll encounter a patchwork of biographies,

Paint him as a multifaceted icon: a smooth-talking 1980s talk-show host, a modern soul musician redefining R&B, or even a cologne-peddling movie star from the 1990s. Yet, dig a little deeper, and the truth emerges—Burt Thicke isn’t real. He’s a digital ghost, a legend born from memes, misremembered celebrities, and the creative whims of online communities.

The phenomenon of Burt Thicke highlights the power of shared narratives in the digital age. With no official records, no birth certificate, and no verifiable achievements, he exists solely through the collective imagination of netizens. Websites dedicate entire pages to his “life and career,” complete with fabricated timelines and glowing reviews. Social media buzzes with ironic tributes, and AI tools churn out images that make him look convincingly retro.

But why does this matter?

In a world saturated with real celebrities, Burt Thicke represents a rebellion—a playful nod to the absurdity of fame and the ease with which we can manufacture it. Over the next 1500 words, we’ll unpack his story, from humble joke origins to his status as a symbol of internet folklore.

Origins: From a Joke to a Digital Myth

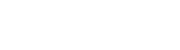

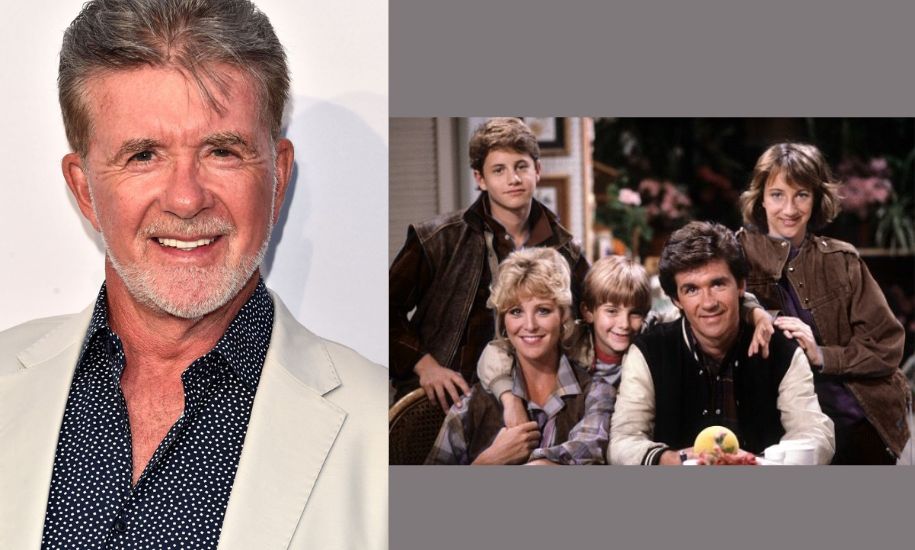

The roots of Burt Thicke trace back to the early 2010s, a time when social media was still finding its footing in shaping cultural narratives. One of the earliest documented mentions appears in a 2014 X (formerly Twitter) post, where user @BettyUtility humorously quipped about the Thicke family tree: “Robin Thicke is sleazy, but his dad Alan Thicke is even sleazier. Mind you, his grandad Burt Thicke was the sleaziest man in Old Hollywood.” This offhand joke, blending the real-life singer Robin Thicke and his father, actor Alan Thicke, with a fictional grandfather, planted the seed. It was a simple gag, playing on the family’s showbiz legacy—Alan was known for hosting “Thicke of the Night” and starring in “Growing Pains,” while Robin gained fame (and infamy) with hits like “Blurred Lines.” But why “Burt”? Analysts suggest it’s a mash-up of Burt Reynolds, the mustachioed icon of 1970s and 1980s masculinity, famous for films like “Smokey and the Bandit” and his role in “All Dogs Go to Heaven.”

Reynolds’ name often surfaces in rumors tied to tragic Hollywood stories, such as the 1988 murder of child actress Judith Barsi. Online threads mistakenly attribute re-recorded lines in “All Dogs Go to Heaven” to a “Burt Thicke,” conflating Reynolds’ involvement with Alan Thicke’s Canadian charm. This misremembering, amplified by forums like Reddit and Tumblr, transformed a typo or joke into a budding legend. By the late 2010s, memes began circulating: retro-styled images of a dashing man in sunglasses, captioned “Approved by Burt Thicke” or paired with fake quotes like “Stay smooth, stay Thicke.”

What started as irony snowballed through algorithms.

Search engines, prioritizing engagement, pushed related content higher, creating a feedback loop. Users searching for “Burt Thicke” found sparse results at first, but as more people joked about him, content creators filled the void. Blogs and AI-assisted articles emerged, each adding layers to his mythos. This mirrors the Mandela Effect, where collective false memories— like believing Nelson Mandela died in prison—create shared realities. In Thicke’s case, people began “remembering” his talk shows or movies, despite no evidence.

The Many Faces of Burt Thicke

One of the most fascinating aspects of Burt Thicke is his chameleon-like identity. Depending on the source, he’s portrayed in wildly different ways, each tailored to evoke nostalgia for bygone eras. In one incarnation, he’s a quintessential 1980s entertainer: a talk-show host with a whiskey-smooth voice, hosting “The Thicke of It” and rubbing shoulders with stars like Tom Selleck or Jane Fonda. Fake filmographies list titles like “Steel & Velvet” (1987), a romantic thriller where he plays a detective with a heart of gold, or “Hard to Burt” (1994), a comedy about a washed-up actor. These details, often accompanied by Photoshopped posters, capture the essence of 80s masculinity—rugged yet polished, confident under good lighting.

Burt Thicke: How the Internet Invented Its Own Legend

Burt Thicke: How the Internet Invented Its Own Legend

This multiplicity underscores the democratized nature of storytelling online. Anyone can contribute: a Reddit thread adds a backstory, a Midjourney prompt generates visuals, and suddenly, Thicke has a “legacy.”

The Role of AI and Memes in His Creation

Central to Burt Thicke’s rise is the interplay of memes and artificial intelligence. Memes, as coined by Richard Dawkins in 1976, are cultural units that spread like genes, evolving through replication and variation. In the digital realm, they thrive on humor and relatability. Thicke’s memes started simple—ironic approvals or absurd quotes—but grew sophisticated with AI tools like DALL-E and Midjourney creating consistent imagery: tall, broad-shouldered, with a charming smile and slicked hair.

AI amplifies this by generating articles, videos, and even “lost episodes” of his shows. Sites like BuzVista and Digital Press publish detailed overviews, treating him as real, which feeds search algorithms and perpetuates the cycle. This raises questions about authenticity: In an age of deepfakes, how do we discern fact from fabrication? Thicke’s story illustrates “manufactured authenticity,” where irony masks genuine nostalgia for pre-digital coolness. Memes about him allow users to express affection for 80s icons without sentimentality, using humor as a shield.

Moreover, platforms reward engagement over truth. A viral TikTok titled “The Greatest Actor You Never Knew” uses AI footage to “reveal” his career, garnering millions of views. This distributed belief system—where repetition creates reality—mirrors how urban legends spread, but accelerated by tech.

Cultural Impact: A Mirror to Online Society

Burt Thicke’s enduring appeal lies in what he reflects about us. He’s a prototype for synthetic media myths, challenging notions of fame in the influencer era. By inventing a celebrity from nothing, the internet rebels against polished, corporate personas, favoring organic (if fictional) charm. He evokes yearning for simpler times—talk shows without ads, soul music with heart—amid today’s content overload.

His story also ties into broader trends like viral usernames and misheard names, showing how curiosity drives traffic. For SEO writers and bloggers, he’s a goldmine: intriguing enough to click, mysterious enough to discuss. As AI advances, expect more “Thickes”—figures born from algorithms, sustained by communities.

In essence, Burt Thicke proves that belief can create reality online. He’s not just a joke; he’s a cultural artifact, reminding us of the internet’s creative, chaotic power.

Conclusion

Burt Thicke may never have existed, but his impact is undeniable. From a 2014 tweet to a sprawling digital lore, he’s become a symbol of how memes, AI, and nostalgia intersect. Whether as a soul crooner, Hollywood heartthrob, or enigmatic speaker, he captivates because he feels familiar yet elusive. In celebrating him, we celebrate the internet’s ability to forge connections through fiction. As one fake quote attributes to him: “Confidence is 80 percent attitude and 20 percent good lighting.” In the glow of our screens, Burt Thicke shines on.